Products

Filter division

|

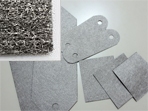

A filter made of a non-woven metal fabric with sintered porous structure. It has metallic properties, such as heat resistance and corrosion resistance, and it is widely used in industrial sector. We can offer a variety of filtrations by using different types of fibers or adjusting basis weight. Its pressure loss is low and it achieved a better filtration performance. Therefore, it is applied as a filter for inkjet printers to print high quality photos.

In addition, it utilizes high porosity and large surface area, and it is also used as electrode material. |

Types and main features of metal fibers

Focusing wire drawing method

|

Manufacturing method and shape

Main materials

Main applications

Characteristic |

Chatter vibration cutting method

|

Manufacturing method and shape

Main materials

Main applications

Characteristic |

Coil cutting method

|

Manufacturing method and shape

Main materials

Main applications

Characteristic |